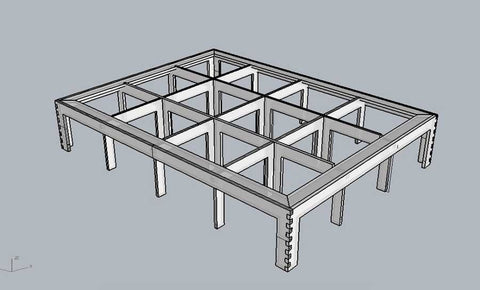

How smart! Make a bed like building blocks

In the choice of bedroom bed, everyone’s aesthetic is different. Today, there is such a group of woodworking enthusiasts who have made reasonable improvements and innovations to traditional wood crafts and created many surprising works. I’m gonna show you this tenon joints bed, which is as simple and fun as building blocks. Let us start!

You should have:

Multilayer boards, panel furniture CNC cutting machines, mattresses, Tootock measuring ruler, Tootock hand planing etc.

You should know:

It is necessary to design every detail of the mortise and tenon bed, then use a cutting machine to open the material, and finally assemble. Assembling is generally first down and then up, pay attention to the assembly of various parts. After assembling, check whether it meets the requirements.

Step 1: Design

The bed design adopts the tenon and tenon structure, and the necessary tenon and tenon pieces are designed, the best joining method, and the most reasonable tenon and tenon process. Whether the joining method of each interface is feasible in the actual process technology, whether the overall structure is reasonable and firm, and the selected materials and cross-sectional dimensions meet the combination requirements.

Step 2: Cutting

First, perform a comprehensive inspection of the panel furniture CNC cutting machine, check whether the link bolts of each part of the cutting machine are loose, and check whether the driving device of the cutting machine runs smoothly. When these have been checked, there is no problem. It can be started up and run normally.

Step 3: Assembly

According to the design structure drawings, prepare the parts and materials that need to be assembled. Take the inspected parts and materials and place them in the assembly space. Then according to the mortise and tenon bed structure assembly drawing, the processed parts are combined into a relatively independent structural component unit. If it is found to be inappropriate, it must be adjusted and replaced in time.

The process of assembling is very demanding on woodworkers. He needs to have a good understanding of the tenon-and-mortise structure and know the connection tips of each tenon-and-mortise structure. Only in this way can he successfully complete the assembly of this tenon-and-mortise bed.

Step 4: Finished!

The whole is assembled and then inspected. The inspection place is mainly to see whether the tenon and tenon joints are tight, firm, and seamless. The structural soul of this assembled bed is the tenon and tenon joint. It does not use a clever combination of nails and glue. The combination of each part is simple and clear, conforms to the principles of mechanics, beautiful and practical, which is the favorite of modern woodworking enthusiasts. s work.

Sample Block Quote

Praesent vestibulum congue tellus at fringilla. Curabitur vitae semper sem, eu convallis est. Cras felis nunc commodo loremous convallis vitae interdum non nisl. Maecenas ac est sit amet augue pharetra convallis nec danos.

Sample Paragraph Text

Praesent vestibulum congue tellus at fringilla. Curabitur vitae semper sem, eu convallis est. Cras felis nunc commodo eu convallis vitae interdum non nisl. Maecenas ac est sit amet augue pharetra convallis nec danos dui.

Cras suscipit quam et turpis eleifend vitae malesuada magna congue. Damus id ullamcorper neque. Sed vitae mi a mi pretium aliquet ac sed elitos. Pellentesque nulla eros accumsan quis justo at tincidunt lobortis denimes loremous. Suspendisse vestibulum lectus in lectus volutpat, ut dapibus purus pulvinar. Vestibulum sit amet auctor ipsum.