Make yourself a wood dining table

This solid wood dining table is made of maple wood as a dining table. The four legs and the front panel are all white maple wood. No matter how popular modern furniture is, the solid wood dining table still has its irreplaceable social status. In addition to buying in the mall, we can also DIY at home. Today, I will share the production process of the solid wood small dining table for the majority of friends.

Tools:

Maple, woodworking saw, woodworking chisel, tootock measuring square, F clip, wire gauge, great woodworking glue, sandpaper, pencil, etc.

Making steps:

Today, I brought a tutorial on the making of a small solid wood dining table. Regardless of the formal dining room, a small dining table in the kitchen is still the most utilized. So, how do DIY make a favorite dining table? First, design the style and size you need, then choose the appropriate wood, then the hand-made structure, and finally the process of polishing and painting, interested wood friends will take a look down.

Step 1: Wood cutting

First, the maple wood is cut, and the thickness is cut according to the size of the small dining table when the material is cut, and then the wood is cut from the opened raw material according to the required size of the table parts, and then it is hand-finished. If the whole wood is cut by oneself, pay attention to the principle that long materials cannot be sawed short, and wide materials cannot be sawed narrowly.

Step 2: Making the table legs

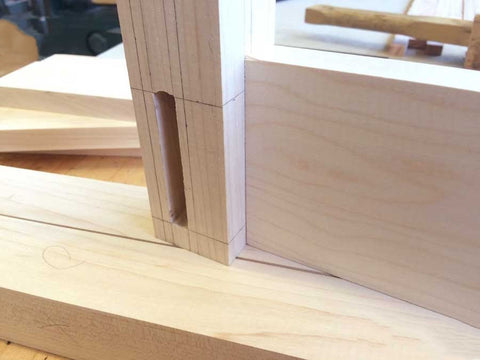

Use a wire gauge on the inner and two sides of the four legs of the dining table to draw a structural diagram of the semi-permeable tenon, and use a table saw to drill the pierced hole according to the scribe line, paying attention to the depth of the pierced hole. Then fix the table legs on the woodworking table with F clips, and then use a hand chisel to trim the squares. Similarly, fix the cut four cross-crotches (two long and two short) on the woodworking table with woodworking clamps, and then use a woodworking saw to cut out the tenon according to the drawn line. The higher the precision of the manufactured tenon, the better.

Step 3: Assemble the leg frame

First put two of the made table legs on the woodworking table, pay attention to the direction and position of the table legs, and then clip the short cross-crotch on the table legs, and then use the F clamp to shape it after installation. After the two pairs of table legs are made, install two long horizontal crotches in the same way. Finally, put the assembled table leg frame on the plane to adjust the level of the table legs and leg frame.

Step 4: Build the desktop

Use the spirit level to adjust the level of the table frame. After the position of the table frame is level, the table top will be made below. First, determine the length and width of the table top according to the size of the table frame. The thickness of the maple board is not less than 2cm, and the panel is cut according to the size requirements. The panel is made of biscuit tenon. The biscuit tenon is easy to process, and the precision is not high, but the strength is high. Then, use sandpaper to grind one side of the table top board first, smooth the uneven part, and then paint it.

Step 5: Done!

The solid wood dining table is not just a dining table of one material. There are many types of solid wood, and solid wood of different materials has different characteristics, and of course there are advantages and disadvantages. Moreover, as long as the solid wood dining table is well maintained, its lifespan is also very long, especially if it is made of tenon and tenon structure, it is more beautiful and firm, and the wooden table is also very helpful to people's health.

Sample Block Quote

Praesent vestibulum congue tellus at fringilla. Curabitur vitae semper sem, eu convallis est. Cras felis nunc commodo loremous convallis vitae interdum non nisl. Maecenas ac est sit amet augue pharetra convallis nec danos.

Sample Paragraph Text

Praesent vestibulum congue tellus at fringilla. Curabitur vitae semper sem, eu convallis est. Cras felis nunc commodo eu convallis vitae interdum non nisl. Maecenas ac est sit amet augue pharetra convallis nec danos dui.

Cras suscipit quam et turpis eleifend vitae malesuada magna congue. Damus id ullamcorper neque. Sed vitae mi a mi pretium aliquet ac sed elitos. Pellentesque nulla eros accumsan quis justo at tincidunt lobortis denimes loremous. Suspendisse vestibulum lectus in lectus volutpat, ut dapibus purus pulvinar. Vestibulum sit amet auctor ipsum.